Why Your Industrial Machinery Needs Automated Lubrication Services

Industrial machines are the backbone of factories, mills, and warehouses around Florence, Kentucky, and beyond. Whether you operate in Kentucky, Tennessee, Ohio, Indiana, Mississippi, or West Virginia, your equipment drives your business. But

machines can't do their job if they aren't well taken care of, and that's where automated lubrication services make all the difference.

What Is Automated Lubrication?

Imagine you own a fleet of delivery trucks. Drivers know they need oil changes, but skip a few and engines start to seize. The same logic applies to industrial machinery. Gears, chains, conveyors, and bearings take a beating through constant motion. They need industrial lubricants to reduce friction and stop wear and tear. Yet, manual greasing is time-consuming and easy to forget.

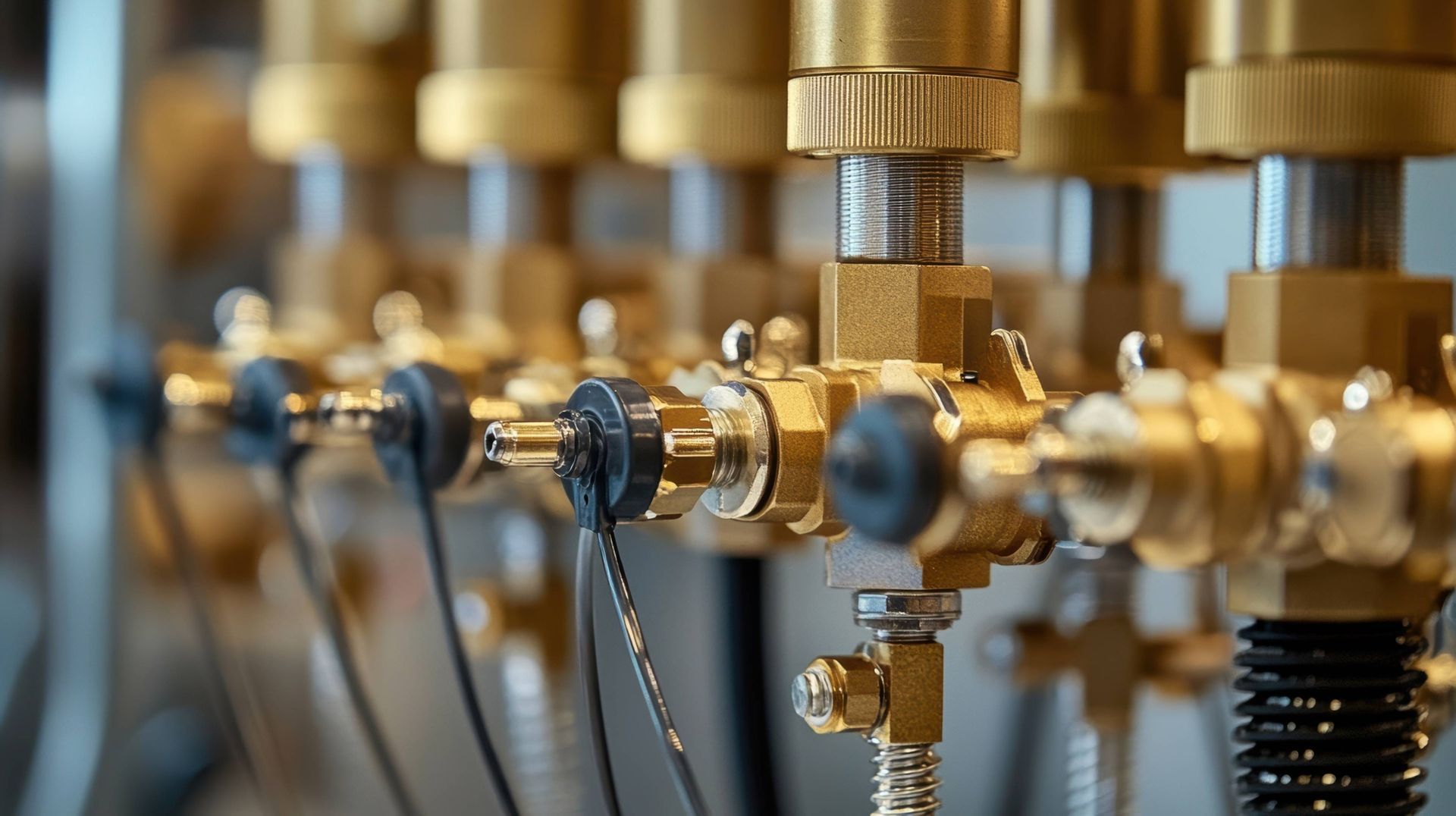

Automated lubrication systems handle all that work for you. Smart pumps and lines deliver the right amount of lubricant to every moving part at specified intervals. No more missed spots. No more over- or under-lubrication.

Benefits That Go Beyond Routine Maintenance

Why does all this matter? Let's count the ways:

- Reduced Downtime: The bottom line suffers from breakdowns. Whole lines may stop for hours or even days when a gearbox fails because of inadequate lubrication. Every component operates smoothly thanks to automated lubrication, which avoids expensive repairs and unplanned downtime.

- Longer Equipment Life: Proper lubrication isn't a luxury; it's a necessity for industrial equipment. Imagine less grinding and fewer repairs. What you get: assets that last years longer. That means stronger returns on every investment.

- Fewer Workplace Accidents: Stuck bearings or overheated motors spell danger for your team. Consistent lubrication reduces equipment failure, which lowers the chance of injuries caused by breakdowns. Everyone stays safer on the job.

- Lower Costs: Manual lubrication takes up labor hours and risks human error. Automated systems cut out waste by applying just enough lubricant right where it's needed. Expect lower oil and grease bills. Stretch your maintenance budget further.

- Cleaner, Greener Operation: Over-lubrication means spills and waste. Under-lubrication leads to worn-out parts landing in landfills too soon. Automated lubrication improves sustainability: clean machines, less waste, and more uptime.

How Do You Know It's Time to Upgrade?

Look for these warning signs:

- Equipment often overheats.

- Unusual noises or vibration.

- Frequent breakdowns or repairs.

- Rising lubricant costs with no result.

If you nodded at any of these, automated lubrication can help.

Connect with Your Industrial Lubrication Services Near Florence, KY

Not all lubrication services are equal. Slick Rollers offers tailored solutions based on your gear, not one-size-fits-all kits. With deep knowledge of industrial lubricants and services, our technicians recommend the best products and set up the system to fit your daily operations. Not the other way around.

Don't let worn parts or downtime slow your shop. Automated lubrication brings precision, safety, and savings to any industrial process. Reliable service from experts near Florence, KY, means support is always close at hand. If you want your industrial machinery working its best, give automated lubrication services a serious look, and let Slick Rollers keep things running smoothly. Based in Florence, KY, Slick Rollers delivers industrial lubrication services all across the Ohio River Valley and Tennessee River Valley.

If you're experiencing challenges keeping your industrial machinery lubricated, call Slick Rollers today at (859) 586-0500. Or contact us through our website.